Inspection service in Taiwan

Service Description

Why product inspection in Taiwan is essential for importers there

Some quantity of product defects or other quality issues is generally unavoidable in mass production—no factory manufactures flawless products 100 percent of the time. And if an order from your supplier in Taiwan has products that don’t conform to your requirements, you may have to spend extra time and money resolving issues in the goods product inspection

But if you conduct verify the goods before they leave the factory, you can avoid extra costs and ensure you’re getting what you’ve paid for. Product inspection in Taiwan allows you to find any problems with your product and address them with your supplier quickly. This helps you limit shipping delays, avoid receiving faulty goods and even prevent a product recall.

Your supplier’s factory likely has an internal QC team in place at their factory. But many importers turn to a third-party inspection company for more thorough and reliable reporting. A professional inspection company offers an unbiased inspection, since their staff aren’t employed by the factory. The challenge for many importers, is finding a third-party that has expertise in their product category.

Product

quality inspection is an effective way to identify problems that is

clue for companies to find out the root case, and implement corrective

actions as soon as possible. It's a win win solution for both customer

and supplier, to ensure that the final product meets customers'

expectations in a cost effective way.

Avoid loss of business by identifying problems before shipment.

First article inspection/initial production inspection

We

performs the first article inspection and initial production inspection

prior to volume production. By this inspection we know clearly about how

much the supplier understand the product specification, verify the

process appropriateness, detect and eliminate the problem proactively.

In process inspection

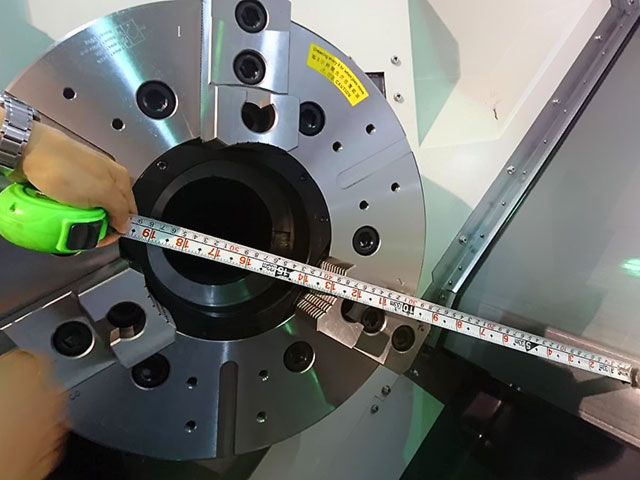

Inspect the samples randomly selected from production process, ensuring that the products or semi finished products conform with the customer specification, address any problem early, besides, the production progress will be evaluated, any issue which can cause the order delay will be identified during the in process inspection.

Final Pre shipment inspection

This pre-shipment inspection (PSI) is carried out when production finishes and at least 80% of the products are packed. The samples are selected for checking at random according to AQL sampling standards and procedures. This PSI service ensures the finished goods to meet your requirement. During pre shipment inspection, QC engineers verify the final finished product quality, evaluate the conformance with cutomer specification, avoid any transportation, reputation and other cost loss caused by quality.